Taurus Auto Drafting Crush Manual

Your safety is our focus

All Te Pari crushes and handlers are designed to deliver the ultimate in safety. At times working with livestock can be a dangerous business so we have designed many features into our Cattle Crushes and head bails to reduce the risk of accidents and injuries.

Ratchets and pawls by their very nature are prone to wear, before starting a session we strongly recommend checking over the operation of your crush with particular attention to the locking action of the head bail. Animal safety is also of great importance, so all our equipment is designed to get the job done with minimal discomfort and distress to the animal.

At Te Pari Products we take quality seriously. We only manufacture from top-quality materials and have thorough and effective quality control systems in place. Our production systems mean our products are of the highest standard, so much so, that from the time of purchase, your Te Pari Cattle Crush carries a full 36-month structural warranty.

General Cattle Handling

Keep calm and in control!

- A calm and decisive operator will help prevent the cattle from becoming alarmed or over-excited. This is one of the most important rules of good cattle handling.

- Quick reflexes are required to catch horned animals, because safety is of primary importance we recommend the baulk gate option is fitted for catching horned animals.

Health and safety

- Keep your hands, fingers and limbs well clear of any pivots, hinges or other pinch points on your crush for example, the head bail doors, and other moving mechanisms.

- If a rear handle option is fitted to your head bail disengage the front handle when using the rear handle and visa versa. This will prevent injuries from the handle not in use hitting other people working around the crush.

- Do not enter the area in front of the crush until you have checked that the animal is fully secured. It is safe work practice to keep clear of this area.

- Whenever possible do not work alone.

- Make sure you read and understand the correct operating procedure for your crush before you use it.

Hand Crush Hazards

- The Taurus HD3 & HD5 Cattle Crush has moving gates positioned in multiple locations.

- Keep hands clear to avoid the risk of a crush injury when the machine is operational.

Taurus Crush Only

Draft out of crush option

This configuration uses the side gates of the Cattle Crush as the sorting gates. Pneumatic rams open and close the side gates automatically. This suits situations that have limited length. The yard design for this set up needs to consider operator safety as the cattle could exit into the working area.

Taurus Crush with 3-Way Draft Gates

Inline drafting option

This configuration is called ‘in line drafting’. The cattle leave the crush and exit out drafting gates in front which automatically open and close. This configuration is very safe and efficient to use and it provides the fastest sequence time.

Taurus Crush with 5-Way Draft Gates

5-way sorting system

For bigger operations needing to sort more than 3 ways, the crush can be configured with a 5-way sorting module.

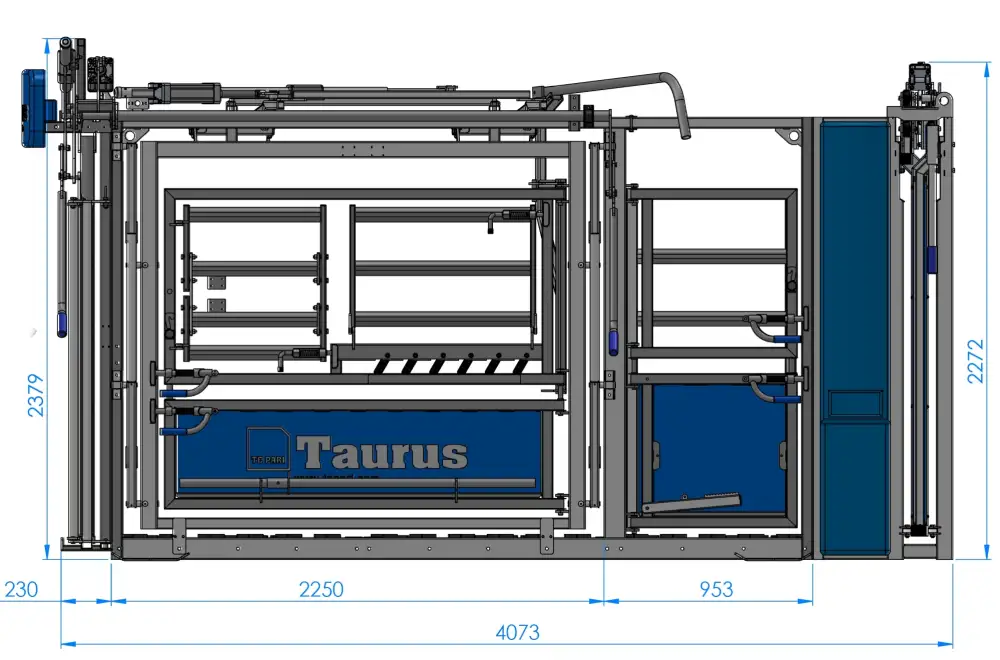

| Dimensions | Taurus Vet Crush | Taurus + 3WD Gates | Taurus + 5WD Gates |

|---|---|---|---|

| Full Length | 4073mm | 7470mm | 9565mm |

| Vet Section | 950mm | 950mm | 950mm |

| Animal Compartment | 2250mm | 2250mm | 2250mm |

| Crush Width | 1500mm | 1500mm | 1500mm |

| Internal Squeeze Width | 340-750mm | 340-750mm | 340-750mm |

| Height | 2380mm | 2380mm | 2380mm |

| Weight | 1168kg | 1260kg | 1620kg |

Note:

All dimensions are shown in millimetres (mm) and all weights are in kilograms (kg). The standard height of all crushes is 2350mm. The operating height of the head bail is 2425mm due to the linkage position. Weights are approximate as they vary depending on fitted options. If the crush is fitted with an offside draft handle or overhead scale pendant the overall height will increase.

* These measurements are the overall length excluding the sign on the head bail, the sign adds about a further 100mm. Add 220mm for the sliding gate if fitted.

If your unloading facility is not capable of lifting the total weight safely unload any additional products that may have been stored inside the crush for transport.

The best option is to use a forklift under the top main chassis rail. Take special care to avoid placing loads upon the shafts and handles.

If you notice any freight damage on arrival, please notify Te Pari Products immediately. We also recommend that you write details of any damage that may have occurred on the drivers copy of the delivery consignment note.

Requirements

- A level concrete surface at least 2.5m wide.

- 2.5hp compressor, 13-16 CFM

- 240V power supply or generator or separate battery

Please read and understand the instructions before operating your Taurus HD3 or HD5 Cattle Crush.

Compressor

We recommend a 13 - 16 CFM belt-driven compressor. If the compressor is too small the Taurus will run slowly and may not operate properly.

The compressor does not need to be close to the crush, in fact having it at some distance reduces noise levels in the working area.

It is important to run compressors in a well-ventilated area as close as possible to a main supply near a switchboard – this avoids the use of leads which can affect the power input.

From time to time the oil level on the dipstick should be checked. Water should be drained from the air reservoir, after every use.

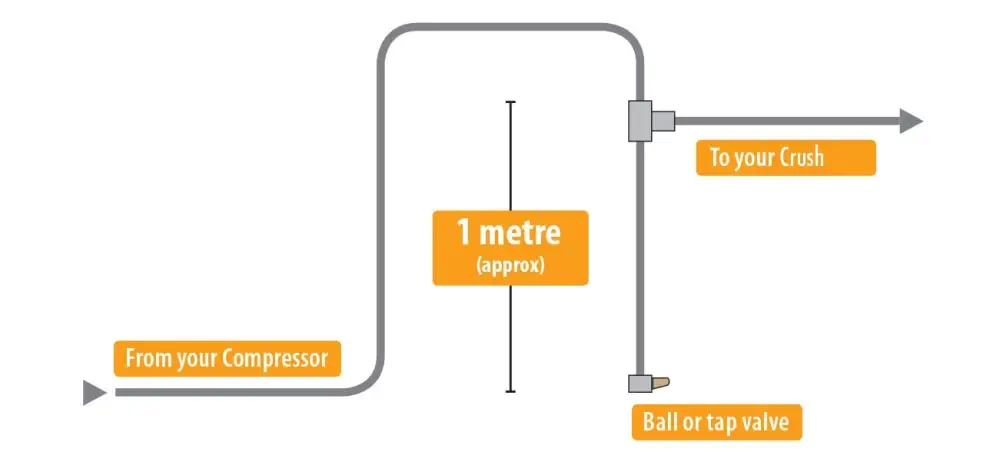

Attaching the air fittings and connecting the compressor

We recommend the airline configuration shown here for the best performance from your compressor and Taurus Auto Drafter.

This provides a purge tap or ball valve, which allows condensation to be periodically removed from the air system. Assemble the airline and connect it to the compressor. Plug the compressor into a power source and turn it on. Finally, turn the compressor on. Always turn the compressor on or off at the unit and not the power source.

NOTE:

When turning the compressor on or off, use the switch on the compressor and not the switch at the power source. This applies to all compressors, because air is not discharged, the compressor is being asked to start under load and this can burn out its capacitor.

Mounting scales

Your Taurus Crush needs to be free-standing in order to accurately weigh animals, so do not attach gates or have anything latching onto or swinging off the crush.

Bolt the load bars underneath the crush to the mounting points on the chassis rail. A flat and level concrete surface will be necessary to ensure accurate weighing.

How it works

The Taurus HD3 system uses compressed air to open and close the entry and various exit gates. After the animal enters the crush the rear sliding gate is automatically closed, and the weighing cycle starts.

When a stable weight is recorded the appropriate exit/drafting gate is automatically opened and the animal is released. With the 5-function handheld radio remote control, the operator can control the main functions of the crush and the draft gates from a distance.

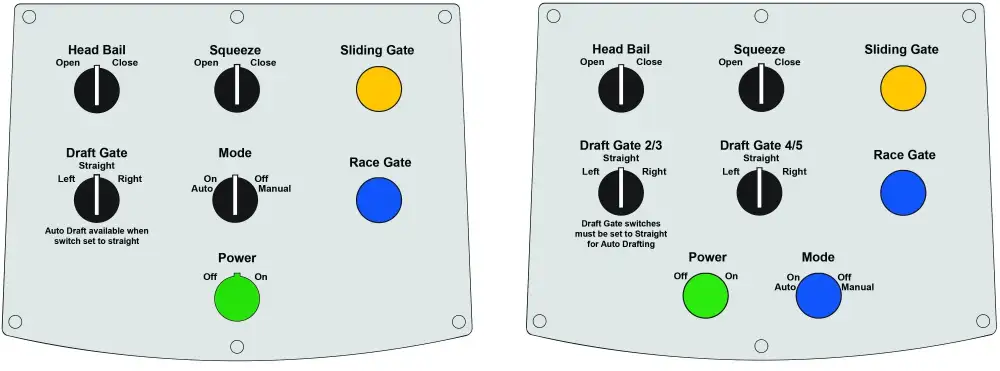

Manual Mode

When the crush is set to Manual mode all control is operated using the switches on the crush or using the remote control.

Manual operation functions:

- Head bail – open or close

- Squeeze – open or close

- Drafting gates – left or right

- Sliding gate – open or close the sliding gate on the crush

- Race gate – open or close the sliding gate in the race (optional item)

Auto Mode

When switched to Auto mode the crush will adjust ready for auto drafting. The head bail will close and the sliding gate will open. The draft gate switch needs to be set to straight or it will override the Auto drafting commands.

When an animal enters it will be detected by a sensor mounted in the top of the crush. This will start the process of closing the sliding gate.

When the sliding gate is closed completely another sensor is activated and a command is sent to the scales to make a drafting decision. This is handled differently per model as noted below:

Crush with 3-Way Draft Module

If the crush has a 3-way draft module the gates will be set in the correct direction and the head bail will open for the animal to exit. As the animal moves through the draft module it will be detected by a sensor and the head bail will close again and a sliding gate will open for the next animal. If an animal remains standing in the draft module (in front of the sensor) the next animal will not be released until the animal has moved on.

Draft out of crush model

When a command is received the gate on the crush will open to let the animal exit. As the weight drops off the gates will close again and the sliding gate will open ready for the next animal.

Taurus Auto Drafting Crush is compatible with:

- Te Pari Macrostock Scales

- Gallagher 610 / 810 / TSI Scales

- Tru-Test XR/ID Series Scales

- Te Pari eRail controller (ASR566) is needed if connected to Tru-Test or Gallagher Scale systems

NOTE: If your remote control is not working then it may need to be programmed to your machine. To do this turn your drafter OFF and then ON again and hold down the ENTRY and RACE buttons for 10 seconds. Paring must be done immediately after the machine is turned on.

The diagrams below explain the operating options on the Taurus HD3 and HD5 Auto Drafters.

Cleaning

For the longevity of your Te Pari Crush, we recommend that it is cleaned down thoroughly after use. Cattle urine and faeces can have a corrosive effect on your equipment. Regularly scrap out underneath your crush to ensure weighing accuracy. We recommend cleaning the crush without the use of water blasters as water can often lead to damaging the load cell(s), which will cause weighing inaccuracies and may require replacement over time.

Lubrication

Lubricate all grease nipples, pivots and tracks on your Te Pari Crush unit at least once per month or every 1,000 animals processed. The nylon wheels on the sliding gate require lubrication once every 2 months. We recommend using a silicon spray, or CRC to perform this task. Slam latches also require regular lubrication to ensure they remain easy to operate and do not start to stiffen.

Checking for wear and damage

Check the headbail lock system for wear and tear at least once every 6 months, or every 1,000 animals processed. The pawls or locking plates on the crush head bail can be turned over to provide a fresh edge - effectively doubling their life.

Annually check pivots and bolts for wear and replace as required. Bolts need to be kept tight on the head bail, as they can become loose over time causing the head bail to become sloppy it will also cause additional wear on the unit.

Contact Te Pari Products, or your local dealer for assistance with product part replacement.

Thank you for your purchase.

Our promise is simple...

It works for you (or we will take it back).

For peace of mind, we offer a manufacturer's warranty on all our products. See our website for more information.