Vetmarker Instruction Manual

Vetmaker

The Vetmarker is a lamb handling chute that puts lambs on their feet when they are released. Lambs are loaded into the Vetmarker where ear marking, vaccinating, castration, drenching etc is done with ease from either side of the chute. The straight rollers, in a deep V, help prevent the lambs getting their legs stuck or escaping. At the base of the Vetmarker, the tail is removed and the lamb is automatically sprayed for fly strike on release if required. The lamb lands on its feet and walks away.

The Vetmarker self locks onto the top rail of your lamb catching pen. The height at the other end of the Vetmarker Chute can be adjusted to suit the person tailing.

One person loads the lambs into the Vetmarker. Your animal health requirements can be performed from either side of the Vetmarker. It may be vaccinating, castrating, drenching, ear marking, ear tagging, docking, tailing or weighing if you have the Vetmarker Weigh Attachment.

When the lamb is released it can be automatically sprayed for fly strike if required.

There is no need to pull the lamb from the chute, as the release system allows the lamb to be released onto it’s feet.

To view an overview video of the Vetmarker go to www.youtube.com and search: Vetmarker Tailing Chute | Overview

Weigh Attachment | Vetmarker

Lambs can be weighed, recorded and EID tagged when they are first loaded into the Vetmarker.

After a lamb has been weighed, it can continue on down the Vetmarker for all the other normal procedures that take place at docking.

The Weigh Attachment clips onto the top of your Vetmarker and has Te Pari Load Cells with compatible leads for Tru-Test and Gallagher indicators.

Cleardale Station | Testimonial

“We bought the Vetmarker for the weighing, basically. We were looking for a better way to weigh our lambs. Once they’re weighed, they go down the Vetmarker chute, they get a couple of injections of vaccination B12, scabby vax, then tailed, as well as the weight being recorded against the EID that’s in their ear. Before we had the Vetmarker we were just doing a sample way, you know, like we’d put them in a bag and literally weigh them with a dial, you know. So yeah, it’s quite different now. We’re not writing anything down. We’re using a EID wand and recording weights on a scale touchscreen. And yeah, it’s saved us so much time. We just used to hold them on a board, you know, and there’d be four people picking up lambs. If you look now, we’ve got two people picking up lambs and then jobs that everybody else is doing, but it’s not just holding onto them anymore. So yeah, it’s great for us to get a weight as easily as what we do and record other traits at the same time is really good.”

Ryan Elser, Cleardale Station

RAKAIA GORGE, NEW ZEALAND

To see the full testimonial video go to www.youtube.com and search:

Cleardale Station Vetmarker

Merino | Vetmarker

The Merino Vetmarker has been developed specifically for use with merino sheep to make muelsing safer and easier. This model is 2m long and has added leg hooks for extra leg restraint. The end section of the chute has no rollers to increase friction and also to make it more hygienic. The Merino Vetmarker can convert back to a Farmer model Vetmarker if required. The spray application is not supplied with the Merino Vetmarker but can be added if it is converted back to a Farmer model. Below are photos of the Merino Vetmarker.

Why Vetmarker?

2 Year Warranty

The Vetmarker comes with a 2 year Warranty on engineering defect from the date of purchase. In the event of a defect under this warranty we will repair the Vetmarker.

This warranty does not cover damages relating to accidents or improper use of the Vetmarker. The spray gun, springs and rollers are not covered under this warranty.

Made In New Zealand

Vetmarker Lamb Handling Chutes are made in New Zealand by Te Pari Products to ensure the highest quality standards.

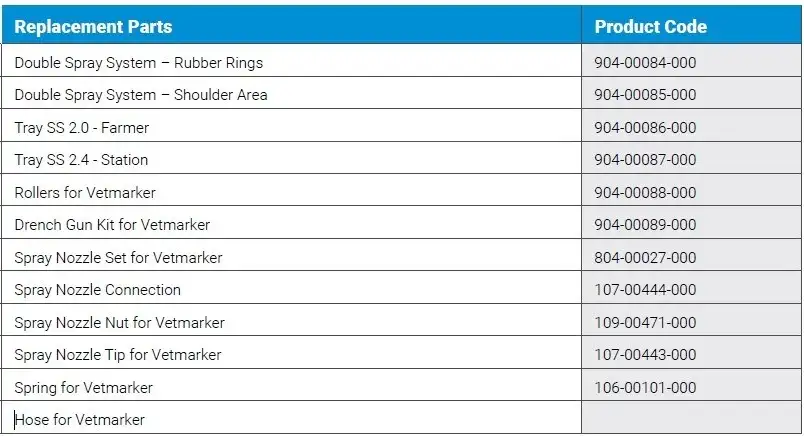

We offer a full range of replacement parts, technical support and after sales service to ensure you get the best return on your investment for many years to come.

Reduces Labour

Vetmarker Lamb Handling Chutes are industry proven to reduce the amount of labour required for lamb handling.

The easy to use designs improve efficiency, and reduce operator fatigue. With the automatic spray unit you will need less staff to get through more lambs in a day.

Vetmarker Set Up | Instructions

Fig 1: Full view of the Vetmarker set up.

To view a video of setting up the Vetmarker go to:

www.youtube.com and search:

Vetmarker Release System Set Up

Fig 2: To attach release handle:

• Take off large spring

• Take out bolts in the handle only

• Line up the handle to the bolt hole in the linkage on the release end

• Don’t over tighten

Fig 3:

• Lock the handle back into position

• Put the spring back on

• Give bolts a lube

Fig 4, 5 & 6:

• Figure 4, 5 and 6 all show close views of the slide bolt set

up.

Fig 7: Attach upright plate with guide rails

• Bolt on heavy upright plate to the main frame of the Vetmarker.

• Then bolt the top arm on top of the upright bar.

Fig 8:

• Looking down on the top plate with top arm bolted in

place.

Fig 9:

• To set up top guide rails it is easier to set it up outside the frame and then attach it to the top arm.

Fig 10a and 10b:

• Bolt the top section of the lamb guide rails to the small

triangle which has an upright pole.

Fig 11:

• Have both the upright poles holding the lamb guide rails on the outside edge of the top arm.

Fig 12:

• Two washers and a spring are then put onto the pole and it is attached to the top arm.

Fig 13:

• Screw the nozzle end into the plate at the end of the Vetmarker.

Fig 14:

• Attach hose and hose clips to pipe and nozzle. The spring over the hose is to protect the hose. The hose can be made more pliable by dipping in hot water to make it easier to push on.

Fig 15:

• Attach hose and hose clips to drench gun and steel hose at release end of Vetmarker.

• Cable tie the hose to frame where it says Vetmarker. Hose from Drench Gun to chemical is not supplied.

Tips & Adjustments

• Always hand prime the drench gun before use to ensure there’s no air locks in the line.

• Always maintain the drench gun.

• Load the Vetmarker with even size lambs.

• Earmark at the loading end of the cradle.

• Apply scabby mouth vaccine near the tailing area.

• Wear protective clothing if spraying.

• Clean and lubricate the Vetmarker at the end of the marking season. Keep a spare release spring in your tool box.

• Solvent based chemicals may damage rollers. Steel rollers can be supplied.

Fig 16 & 17:

Gap between main frame and release end

After a period of time, this slide bolt may need adjusting to compensate for wear in the linkages. The bolt only requires adjustment of a few millimetres in the direction of the arrow. Take off the spring, pull handle forward, loosen slide bolt and slide in direction of arrow a few millimetres. Tighten up and test.

Fig 18:

How to remove rollers

To pull out rollers, reach underneath and pull out the pin. It comes out about 1cm. Steel rollers are supplied by request for people who use solvent based chemicals.

Fig 19:

Drench gun return bungee cord

If you are working in heavy conditions it may help to use a bungee cord to ensure the handle comes back every time. Attach the cord to the handle of the drench gun and pull cord along and attach other end to part of main frame.

Spray Unit

The spray unit works on a full stroke. Once the handle is unlocked the spray automatically activates during the release of the lamb. The speed the handle is pulled dictates the area the spray

covers. A slow release will cover mainly the crutch area. The faster speed will cover from the crutch and over the rump. There are variables that affect the spray area covered such as the lamb size and chemical used. The best operation is to pull the handle on a continuous full stroke.

An example using the double spray system for rubber rings set at 18mls.

Double Spray System Set Up | Instructions

For any farmers, particularly those who use rubber rings or merino sheep where spray is required in the shoulder area. It is essential to increase the spray rate to penetrate both areas.

Fig 20:

• Join the three lengths of hose together with the brass T-Nozzle and tighten with hose clips.

Fig 21:

• Join the hose to the drench gun and spray nozzle. Cable tie onto frame.

Fig 22:

• The picture shown is for farmers using rubber rings. If you are doing the merino spray the hose will go to the nozzle set up in the main part of the Vetmarker.

Fig 23:

The spray nozzle for Merino is set into the channel on themain frame of the Vetmarker. The hose is attached from underneath as shown above. The spray reaches the purse and shoulder areas.

Drench Gun Set Up | Instructions

Always hand-prime the drench gun to start. This will ensure that there is no air in the line. If there is air in the line, the lambs will not be getting the full application of fly strike spray. Hand priming the drench gun will also make you aware of other issues that may arise such as:

• Dirty water or tubing

• Frost damage or blockage

• Dirt in the nozzle

• Chemicals which have crystallized

• Sticky drench gun valve

• Other contaminants blocking the line, drench gun or nozzle.

It is necessary to hand prime the drench gun again after shifting sites or replacing the drum of fly strike chemical.

Instructions:

To set up the drench gun take the rollers out around the mounting area.

Fig 24:

• This view is looking from the inside of the Vetmarker

to the outside.

Fig 25:

• Place the main frame of the drench gun handle inbetween the two steel plates and level the drench

gun so that the black internal piece of plastic (above the internal tension spring) is set just above the steel plate.

• Level it up to make sure that the drench gun is not too high so that it doesn’t interfere with the rollers.

• Tighten bolts.

• Don’t tighten the bolt that holds the pull rod too tight as it needs to be able to move freely.

• It may be necessary to loosen it before use.

Fig 26:

• This photo shows the drench gun with the internal valves positioned the way they should be inserted into the gun.

• It may be necessary to lube these valves if you have a sticky drench gun.

Setting Spray Dose Rate | Instructions

Start by setting the drench gun at 20mls.

Fig 27:

• For a dose rate of 20mls, locate the slide bolt to nearly the top of the slot. Set the T-Bar firmly against the drench gun handle when set at 20mls and tighten the T-Bar lock nuts as shown below.

• Test by pulling the release handle.

Fig 28:

• To achieve a 10ml dose DO NOT adjust the T-Bar. Position the slide bolt at the bottom of the slot. This will adjust the gun to set on 15 and stop at 5.

• The dose rate for spray is adjusted with this slot. Near the top is 20mls. At the bottom is 10mls.

• For a rate lower than 10mls, lock the drench gun handle at the 10ml position, in this set up and back off the T-Bar.

Fig 29:

• Set the T-Bar firmly against the drench gun handle and tighten nuts after you have set the dose rate.

Spare parts are available, please contact your nearest Te Pari branch for servicing and more information.